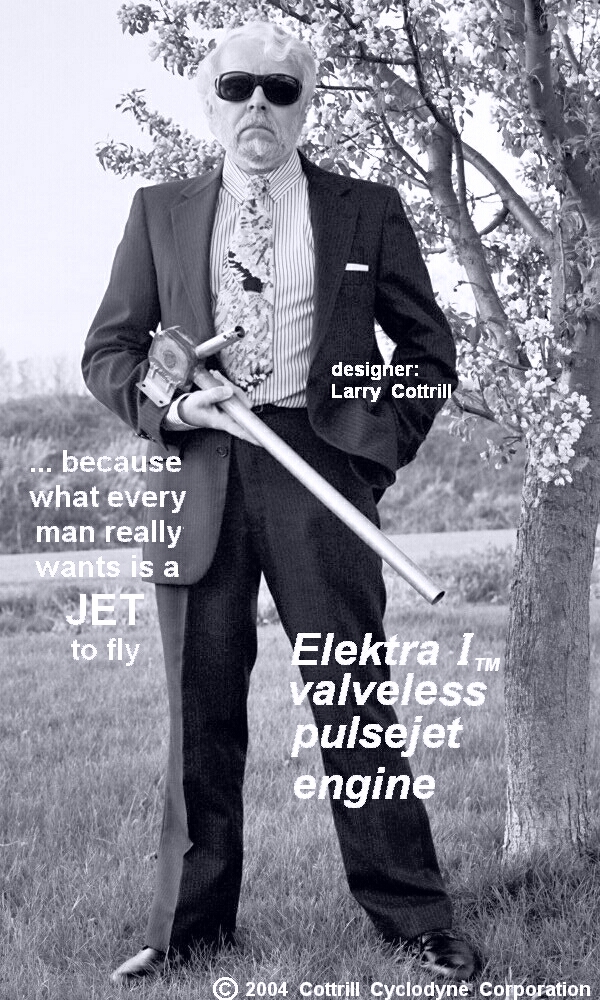

Photo Diary: Building the "Elektra I" Ultra-Low-Cost

Valveless Pulsejet, using ordinary hand tools and LESS THAN

FIVE DOLLARS worth of home improvement store materials

and a spark plug - PART I

by Larry Cottrill, Editor, jetZILLA Online Magazine

- All photos this page Copyright 2003 Larry Cottrill -

Table of Contents [Sections I-V below]:

I. Forming the combustion chamber [09 April 2004]

II. Welding the basic structure [10 April 2004]

III. Closing the chamber [13 April 2004]

IV. The fuel supply tube [16 April 2004]

V. Engine mounts [17 April 2004]

Table of Contents [Test Journal: Sections VI & higher go to Page 2]:

I. Forming the combustion chamber [09 April 2004]:

Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

Starting to enlarge the exhaust port knockout hole - here, I'm

using a large round file to quickly rough out the hole to the much

larger size needed [around 1.25 inches - a little larger than the

OD of the 1-inch conduit exhaust pipe material!]:

A large half-round is needed, though, to really get the

hole smooth and uniformly round [as near a perfect circle

as you can make it]:

A large half-round is needed, though, to really get the

hole smooth and uniformly round [as near a perfect circle

as you can make it]:

Creating the port for the intake stack - Make a punch mark in

the middle of the rounded corner. Then, start the hole with a

small, fast hand drill with a very small twist drill in the chuck

[3/32-inch diam. shown] and a few drops of light oil. Your twist

drill must be good and sharp to start without skidding off:

Creating the port for the intake stack - Make a punch mark in

the middle of the rounded corner. Then, start the hole with a

small, fast hand drill with a very small twist drill in the chuck

[3/32-inch diam. shown] and a few drops of light oil. Your twist

drill must be good and sharp to start without skidding off:

Re-drilling the stack port - Use the biggest drill you have, and make

sure the box is well anchored in the vise. Take it slow, and gradually work

through the steel, using added oil as needed. This is a 3/8-inch twist

drill in a big, slow 1/2HP gearhead drill:

Re-drilling the stack port - Use the biggest drill you have, and make

sure the box is well anchored in the vise. Take it slow, and gradually work

through the steel, using added oil as needed. This is a 3/8-inch twist

drill in a big, slow 1/2HP gearhead drill:

Enlarging the intake stack port, using the full-round file. This

is a LOT of work, but it just needs to be big enough for the 3/4-inch

conduit to slip through. Then, re-work it at the top and bottom to

make it slightly elliptical, so the conduit will fit at the steeper

angle [about 60 degrees] shown in the drawing:

Enlarging the intake stack port, using the full-round file. This

is a LOT of work, but it just needs to be big enough for the 3/4-inch

conduit to slip through. Then, re-work it at the top and bottom to

make it slightly elliptical, so the conduit will fit at the steeper

angle [about 60 degrees] shown in the drawing:

Making the spark plug hole - since I planned to use a miniature plug,

I just used the two-drill technique once more to drill a 3/8-inch hole,

then enlarged it slightly with the full-round file. The drilling and

filing have to be done with great care, so the knockout won't be bent

out of shape. It will end up being welded into the box. [NOTE: If

you use a bigger plug, like a lawnmower plug, just remove the

knockout instead]:

Making the spark plug hole - since I planned to use a miniature plug,

I just used the two-drill technique once more to drill a 3/8-inch hole,

then enlarged it slightly with the full-round file. The drilling and

filing have to be done with great care, so the knockout won't be bent

out of shape. It will end up being welded into the box. [NOTE: If

you use a bigger plug, like a lawnmower plug, just remove the

knockout instead]:

After about an hour's work, here's the finished combustion chamber,

all ready for welding:

After about an hour's work, here's the finished combustion chamber,

all ready for welding:

II. Welding the basic structure [10 April 2004]:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

I started the welding by simply sealing up the knockouts in the

center of the cover plate and in the center of the wide face of

the box - only the slightest amount of filler rod is needed to

get started, then just work the puddle around the knockout:

II. Welding the basic structure [10 April 2004]:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

I started the welding by simply sealing up the knockouts in the

center of the cover plate and in the center of the wide face of

the box - only the slightest amount of filler rod is needed to

get started, then just work the puddle around the knockout:

The smaller 'Romex' knockouts are more difficult, because in this

case, there are some real gaps to be filled:

The smaller 'Romex' knockouts are more difficult, because in this

case, there are some real gaps to be filled:

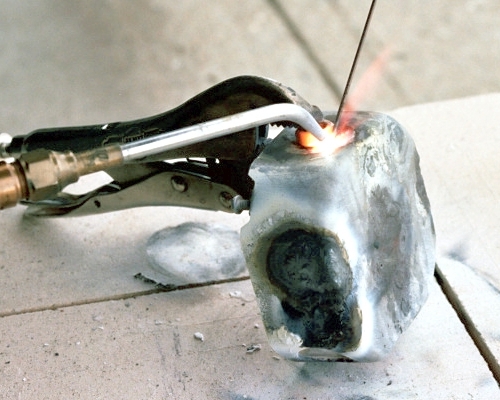

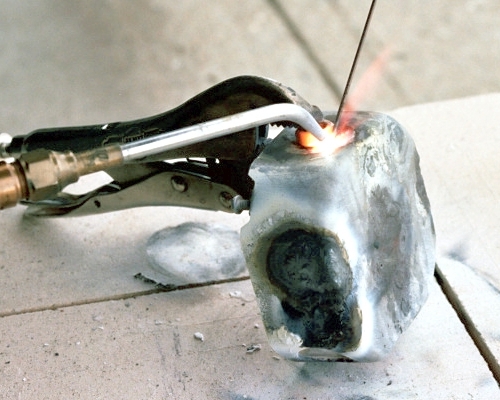

After carefully welding the spark plug knockout to the box, the

spark plug nut is precisely aligned over the hole, and secured with

Vise Grips(TM) pliers while tying the nut down with a couple of

small tack welds:

After carefully welding the spark plug knockout to the box, the

spark plug nut is precisely aligned over the hole, and secured with

Vise Grips(TM) pliers while tying the nut down with a couple of

small tack welds:

After tacking, remove the tool and work carefully around the nut

to get it fully welded in, using filler rod as required. Then,

file the top of the nut back to a smooth surface:

After tacking, remove the tool and work carefully around the nut

to get it fully welded in, using filler rod as required. Then,

file the top of the nut back to a smooth surface:

Unfortunately, the threads will have to be cleaned up by running

a tap of the correct size through the nut.

Now, clamp the box in a vise and position the tailpipe [cut from

1-inch diameter rigid steel conduit] in place, and make a single

large tack weld, leaving about a 1/16-inch gap between the pipe

and the edge of the slightly oversize hole:

Unfortunately, the threads will have to be cleaned up by running

a tap of the correct size through the nut.

Now, clamp the box in a vise and position the tailpipe [cut from

1-inch diameter rigid steel conduit] in place, and make a single

large tack weld, leaving about a 1/16-inch gap between the pipe

and the edge of the slightly oversize hole:

Then, carefully align the pipe with the chamber and make another

tack weld opposite the first one. Next, make two more at 90 degrees

from the first two, being careful to align the pipe as accurately

as possible!

Looking through the chamber at the exhaust stack held in place

by the four tack welds [note the clearly visible space between the

chamber exhaust port and the pipe end]. The finished spark plug

mount is also clearly seen here, in the middle of the nearest wall

[i.e. the front end] of the chamber:

Then, carefully align the pipe with the chamber and make another

tack weld opposite the first one. Next, make two more at 90 degrees

from the first two, being careful to align the pipe as accurately

as possible!

Looking through the chamber at the exhaust stack held in place

by the four tack welds [note the clearly visible space between the

chamber exhaust port and the pipe end]. The finished spark plug

mount is also clearly seen here, in the middle of the nearest wall

[i.e. the front end] of the chamber:

After finishing the complete weld between the exhaust pipe and

the chamber, the intake stack is cut to size, carefully positioned

and tack welded in at one point only:

After finishing the complete weld between the exhaust pipe and

the chamber, the intake stack is cut to size, carefully positioned

and tack welded in at one point only:

The stack is carefully aligned, and the angle checked to make sure

that the angled cutoff is accurately positioned. Then, after a couple

more tack welds and re-checking, it is welded solidly in place. It's

good to have the vise available for positioning the work so that the

entire joint is easy to reach:

The stack is carefully aligned, and the angle checked to make sure

that the angled cutoff is accurately positioned. Then, after a couple

more tack welds and re-checking, it is welded solidly in place. It's

good to have the vise available for positioning the work so that the

entire joint is easy to reach:

The combustion chamber section of the Elektra I engine, all finished

except for welding on the side cover plate:

The combustion chamber section of the Elektra I engine, all finished

except for welding on the side cover plate:

III. Closing the chamber [13 April 2004]:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

The cover plate is attached to the side of the chamber by means of

the two screws. Start the welding process by tack welding the cover

plate at points near the corners:

III. Closing the chamber [13 April 2004]:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

The cover plate is attached to the side of the chamber by means of

the two screws. Start the welding process by tack welding the cover

plate at points near the corners:

Now, remove the two screws holding the plate to the box and finish

weld the edge of the cover plate down to the box wall, working from

tack weld to tack weld. There is enough overhang at the edge of the

coverplate to make almost the entire weld without filler rod -- the

rod is only needed when you get to the corner voids:

Now, remove the two screws holding the plate to the box and finish

weld the edge of the cover plate down to the box wall, working from

tack weld to tack weld. There is enough overhang at the edge of the

coverplate to make almost the entire weld without filler rod -- the

rod is only needed when you get to the corner voids:

The finished combustion chamber section of the Elektra I engine, left side

rear and top view:

The finished combustion chamber section of the Elektra I engine, left side

rear and top view:

The combustion chamber section of the Elektra I engine, right side front

and bottom view:

The combustion chamber section of the Elektra I engine, right side front

and bottom view:

The combustion chamber section of the Elektra I engine, closeup right

side view with spark plug threaded in, just to see how it looks:

The combustion chamber section of the Elektra I engine, closeup right

side view with spark plug threaded in, just to see how it looks:

IV. The fuel supply tube [16 April 2004]:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

The original fuel supply tube is designed to drop into place and

be held by gravity alone. It is .125 inch OD copper tubing, with a

1/4-inch compression fitting bonded on with J-B Weld epoxy. It

slides loosely into a short section of .25 inch OD stainless tubing,

bonded inside the intake tube with J-B Weld. A notch in the near

side of the intake tube rim keeps it in alignment and prevents it

from vibrating out of place. This crude design allows for great

flexibility in experimenting with different fuel schemes:

IV. The fuel supply tube [16 April 2004]:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

The original fuel supply tube is designed to drop into place and

be held by gravity alone. It is .125 inch OD copper tubing, with a

1/4-inch compression fitting bonded on with J-B Weld epoxy. It

slides loosely into a short section of .25 inch OD stainless tubing,

bonded inside the intake tube with J-B Weld. A notch in the near

side of the intake tube rim keeps it in alignment and prevents it

from vibrating out of place. This crude design allows for great

flexibility in experimenting with different fuel schemes:

V. Engine mounts [17 April 2004]:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

The two identical engine mounts are cut from a single hardware piece

called a 'fence rail bracket' - I used the jeweler's saw because it is

a favorite tool, but a hacksaw would have made quicker work of it [the

only other work needed before welding the mounts is to drill out the

holes to a larger size to fit the mounting bolts]:

V. Engine mounts [17 April 2004]:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

The two identical engine mounts are cut from a single hardware piece

called a 'fence rail bracket' - I used the jeweler's saw because it is

a favorite tool, but a hacksaw would have made quicker work of it [the

only other work needed before welding the mounts is to drill out the

holes to a larger size to fit the mounting bolts]:

Jigging the engine and mounts for tack welding - I used a scrap of flat

wood, though metal would be safer. To protect the wood from the torch

flame while tack welding, I covered as much as I could with the sheet

metal scraps shown. The engine itself is supported level by a brick

placed under the tailpipe:

Jigging the engine and mounts for tack welding - I used a scrap of flat

wood, though metal would be safer. To protect the wood from the torch

flame while tack welding, I covered as much as I could with the sheet

metal scraps shown. The engine itself is supported level by a brick

placed under the tailpipe:

Initial joining of the mounts to the engine, using just a couple of

small tack welds - the wood base got scorched in a couple of places;

if you use wood as I did, keep your fire extinguisher handy! After

the tack welding is done and the piece cools, unbolt it carefully

from the jig and do the finish welding, handling carefully so the

alignment isn't accidentally altered.

Initial joining of the mounts to the engine, using just a couple of

small tack welds - the wood base got scorched in a couple of places;

if you use wood as I did, keep your fire extinguisher handy! After

the tack welding is done and the piece cools, unbolt it carefully

from the jig and do the finish welding, handling carefully so the

alignment isn't accidentally altered.

After finish welding the mounts and attaching the fuel pipe and

spark plug, we get our first look at the finished Elektra I pulsejet

prototype:

After finish welding the mounts and attaching the fuel pipe and

spark plug, we get our first look at the finished Elektra I pulsejet

prototype:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

All film processing and negative

scanning for this page was done by

Multi Media Imaging

1526 Walnut Street

Des Moines, Iowa USA 50309

515-309-3456

www.YourProLab.com

All film processing and negative

scanning for this page was done by

Multi Media Imaging

1526 Walnut Street

Des Moines, Iowa USA 50309

515-309-3456

www.YourProLab.com

|

|