Photo Diary: Building and running 'The Short Lady'

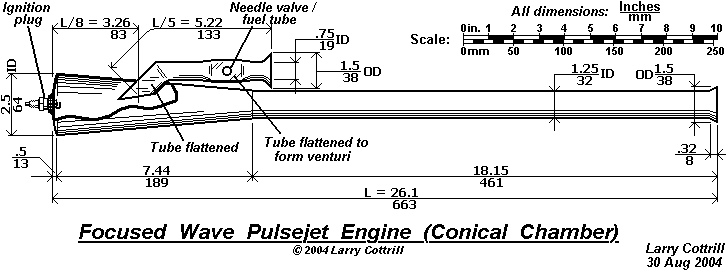

Focused Wave Valveless Pulsejet Engine

by Larry Cottrill, Editor, jetZILLA Online Magazine

- All photos Copyright 2004 Steve Bukowsky and Larry Cottrill -

Steve Bukowsky's original 'Short Lady' build, in good lean running

on propane vapor fuel - exhaust ejection from the rear-facing intake

can be clearly seen in this photo. This shows Steve's final method

of supplying fuel vapor straight down the center of the intake.

Steve's 'Short Lady' started and ran on the very first try!

Photo Copyright 2004 Steve Bukowsky

I. Getting started - "parts is parts":

Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

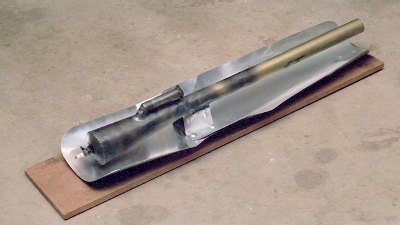

Not having an equipped shop, I had no good way of rolling the

combustion chamber wall and end cones myself. Since Steve had

obviously done such a nice job making these in his school shop,

I negotiated with him to make two sets of cones for me, at a

very reasonable price. Here is Steve's shot of the combustion

chamber parts as he was working on them for me, alonside his

finished 'Short Lady' engine. Note that the wall cones are fully

formed and tack welded in this shot; the front end cones [which

I call "domes"] are cut but not yet rolled and tacked:

Steve Bukowsky's original 'Short Lady' build, in good lean running

on propane vapor fuel - exhaust ejection from the rear-facing intake

can be clearly seen in this photo. This shows Steve's final method

of supplying fuel vapor straight down the center of the intake.

Steve's 'Short Lady' started and ran on the very first try!

Photo Copyright 2004 Steve Bukowsky

I. Getting started - "parts is parts":

Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

Not having an equipped shop, I had no good way of rolling the

combustion chamber wall and end cones myself. Since Steve had

obviously done such a nice job making these in his school shop,

I negotiated with him to make two sets of cones for me, at a

very reasonable price. Here is Steve's shot of the combustion

chamber parts as he was working on them for me, alonside his

finished 'Short Lady' engine. Note that the wall cones are fully

formed and tack welded in this shot; the front end cones [which

I call "domes"] are cut but not yet rolled and tacked:

Photo Copyright 2004 Steve Bukowsky

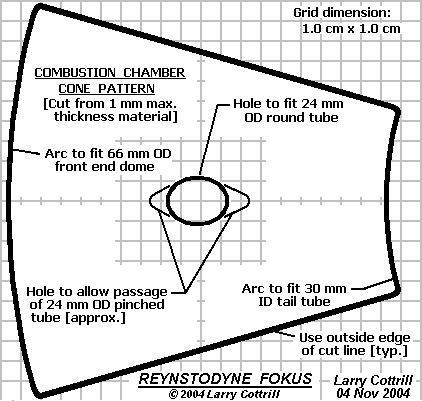

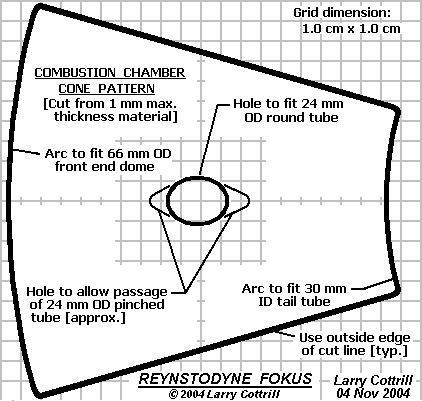

If you have a way of smoothly rolling your own cones, you can

print these graphics and scale them up so the squares form a

1 cm grid, then cut out the patterns to make your own cones

out of 1 mm sheet steel. If you want, you can make the hole

for the intake after rolling and welding the main cone, but

you can still use the pattern to locate the hole accurately.

If you want to use a pinched intake pipe [recommended], use

the longer, diamond-shaped hole outline. Important: You

should use the outside edge of each heavy black outline

as your cut line.

Main Combustion Chamber Cone Pattern

Photo Copyright 2004 Steve Bukowsky

If you have a way of smoothly rolling your own cones, you can

print these graphics and scale them up so the squares form a

1 cm grid, then cut out the patterns to make your own cones

out of 1 mm sheet steel. If you want, you can make the hole

for the intake after rolling and welding the main cone, but

you can still use the pattern to locate the hole accurately.

If you want to use a pinched intake pipe [recommended], use

the longer, diamond-shaped hole outline. Important: You

should use the outside edge of each heavy black outline

as your cut line.

Main Combustion Chamber Cone Pattern

Scalable pattern for the combustion chamber cone - Copyright 2004 Larry Cottrill

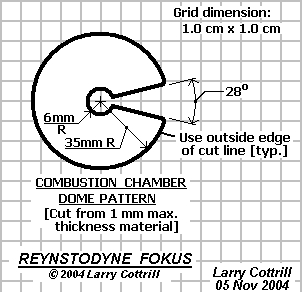

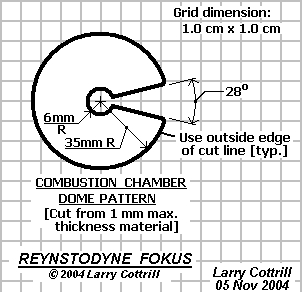

Combustion Chamber Dome Pattern

Scalable pattern for the combustion chamber cone - Copyright 2004 Larry Cottrill

Combustion Chamber Dome Pattern

Scalable pattern for the combustion chamber dome - Copyright 2004 Larry Cottrill

II. Preliminary welding:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

The combustion chamber wall cone side seam was welded in several

passes, to minimize distortion. The three tack welds were blended

in, but left pretty good sized lumps; I simply dressed them down

later on, using a flat file. Both cones I prepared looked just fine, but

were slightly out of round from welding. This was easily corrected

by careful squeezing in the bench vise later:

Scalable pattern for the combustion chamber dome - Copyright 2004 Larry Cottrill

II. Preliminary welding:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

The combustion chamber wall cone side seam was welded in several

passes, to minimize distortion. The three tack welds were blended

in, but left pretty good sized lumps; I simply dressed them down

later on, using a flat file. Both cones I prepared looked just fine, but

were slightly out of round from welding. This was easily corrected

by careful squeezing in the bench vise later:

Similarly, the front end dome seams were quickly finish welded:

Similarly, the front end dome seams were quickly finish welded:

III. Spark plug mount:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

Here's a shot of spark plug mount welding technique. The center

hole in the dome was filed out just enough for a 3/8-24 bolt to go

through from behind, and a nut tightened on. Two more nuts [which

appear white in the photo] are threaded finger tight on top of that,

to protect the bolt threads from the torch heat. This weld takes a

fair amount of heat and filler rod, and you have to be careful not to

slop any weld metal onto the outer nuts, so they can be removed

easily afterward:

III. Spark plug mount:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

Here's a shot of spark plug mount welding technique. The center

hole in the dome was filed out just enough for a 3/8-24 bolt to go

through from behind, and a nut tightened on. Two more nuts [which

appear white in the photo] are threaded finger tight on top of that,

to protect the bolt threads from the torch heat. This weld takes a

fair amount of heat and filler rod, and you have to be careful not to

slop any weld metal onto the outer nuts, so they can be removed

easily afterward:

After cooling, I applied penetrating oil and loosened the nuts.

Removing the outer nuts was easy, but the bolt had to be extracted

from the welded nut using a box-end wrench from behind while

gently gripping the dome in the bench vise. Here's the finished

product, with the second dome in the background, waiting to be

done in the same way:

After cooling, I applied penetrating oil and loosened the nuts.

Removing the outer nuts was easy, but the bolt had to be extracted

from the welded nut using a box-end wrench from behind while

gently gripping the dome in the bench vise. Here's the finished

product, with the second dome in the background, waiting to be

done in the same way:

IV. Welding on the tailpipe tube:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

Next, the tailpipe tube was cut from a piece of TV antenna mast

tubing. I found that for a perfect fit between the combustion

chamber cone and the tailpipe tube, the front end of the tube had

to be expanded a fraction of an inch. This was done by heating

and gentle nudging all around with a small ball peen hammer until

it was a near-perfect fit. Then, I set up a careful 'temporary jig'

of firebrick to hold the pieces in alignment for tack welding.

Proper alignment was established by sighting down the tube from

the rear and adjusting as needed during tack welding. Finally, the

finish weld was run around the seam in four passes, concentrating

on using a minimum of filler rod to try to keep the inside

surface as smooth as possible. Here's a shot of the tack welding

operation, showing the firebrick 'jigging' - note the plain brick

at the rear, pinning the tailpipe to hold it steady:

IV. Welding on the tailpipe tube:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

Next, the tailpipe tube was cut from a piece of TV antenna mast

tubing. I found that for a perfect fit between the combustion

chamber cone and the tailpipe tube, the front end of the tube had

to be expanded a fraction of an inch. This was done by heating

and gentle nudging all around with a small ball peen hammer until

it was a near-perfect fit. Then, I set up a careful 'temporary jig'

of firebrick to hold the pieces in alignment for tack welding.

Proper alignment was established by sighting down the tube from

the rear and adjusting as needed during tack welding. Finally, the

finish weld was run around the seam in four passes, concentrating

on using a minimum of filler rod to try to keep the inside

surface as smooth as possible. Here's a shot of the tack welding

operation, showing the firebrick 'jigging' - note the plain brick

at the rear, pinning the tailpipe to hold it steady:

The finish weld is reasonably reinforced, smooth inside, and

holds the chamber in near-perfect alignment with the tube

[smoothness is critical here; a slight error in alignment is of

no consequence]:

The finish weld is reasonably reinforced, smooth inside, and

holds the chamber in near-perfect alignment with the tube

[smoothness is critical here; a slight error in alignment is of

no consequence]:

V. Fitting and welding in the intake tube:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

Steve followed my design exactly, using 3/4-inch EMT [rigid

electrical conduit] to built his intake tube and flattening the

lower end slightly. The hole in the chamber has to be placed as

accurately as possible to the design location shown on the

drawing. Note that Steve chose to fit his intake as practically

the last step in building his engine - note, too, the beautiful

intake flare hand-formed from sheet metal and welded onto the

outer end of the tube:

V. Fitting and welding in the intake tube:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

Steve followed my design exactly, using 3/4-inch EMT [rigid

electrical conduit] to built his intake tube and flattening the

lower end slightly. The hole in the chamber has to be placed as

accurately as possible to the design location shown on the

drawing. Note that Steve chose to fit his intake as practically

the last step in building his engine - note, too, the beautiful

intake flare hand-formed from sheet metal and welded onto the

outer end of the tube:

Photo Copyright 2004 Steve Bukowsky

Based on Steve's experience running his build of this engine,

I felt I could try reducing the intake to 5/8-inch EMT. Also,

I decided to leave the tube round over its whole length because

of this smaller internal diameter. I formed my flare just by

heating and hammering, and mine is not as smoothly formed as

Steve's finely crafted example. The hole is formed by drilling and

then hand finishing with large and small round files, trying to get

the most precise location and fit possible:

Photo Copyright 2004 Steve Bukowsky

Based on Steve's experience running his build of this engine,

I felt I could try reducing the intake to 5/8-inch EMT. Also,

I decided to leave the tube round over its whole length because

of this smaller internal diameter. I formed my flare just by

heating and hammering, and mine is not as smoothly formed as

Steve's finely crafted example. The hole is formed by drilling and

then hand finishing with large and small round files, trying to get

the most precise location and fit possible:

I wanted to mount the intake tube before welding on the front

dome so that it would be possible to visually inspect the lower

end of the tube for perfect alignment in the middle of the chamber.

I jigged the intake for tack welding by using a 5/16-inch bolt and

nut and an old C-clamp, set just tight enough to hold it:

I wanted to mount the intake tube before welding on the front

dome so that it would be possible to visually inspect the lower

end of the tube for perfect alignment in the middle of the chamber.

I jigged the intake for tack welding by using a 5/16-inch bolt and

nut and an old C-clamp, set just tight enough to hold it:

The end result - the intake tube, finish welded into the chamber wall:

The end result - the intake tube, finish welded into the chamber wall:

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

Previous section Next section Back to Contents Top of page To top of page 2

Subscribe to jetZILLA Online Magazine (it's FREE!)

All film processing and negative

scanning for Larry's shots was done by

Multi Media Imaging

1526 Walnut Street

Des Moines, Iowa USA 50309

515-309-3456

www.multi-media-inc.com

All film processing and negative

scanning for Larry's shots was done by

Multi Media Imaging

1526 Walnut Street

Des Moines, Iowa USA 50309

515-309-3456

www.multi-media-inc.com

|

|

Scalable pattern for the combustion chamber cone - Copyright 2004 Larry Cottrill

Combustion Chamber Dome Pattern

Scalable pattern for the combustion chamber cone - Copyright 2004 Larry Cottrill

Combustion Chamber Dome Pattern

Scalable pattern for the combustion chamber dome - Copyright 2004 Larry Cottrill

Scalable pattern for the combustion chamber dome - Copyright 2004 Larry Cottrill